Project Description

Ballard, Kenall, and Freese and Nichols (Ballard/KFNI) provided A-E services to the Fort Polk Joint Readiness Training Center (JRTC). FNI is the mentor firm in an 8(a) Mentor Protégé JV with Kenall through USACE Fort Worth IDC No. W9126G-17-D-0011 with Kenall. The Task Order (6A) deliverable was issued as a RFP for a Design Bid Build Project.

The task order was part of a larger project that included a total of forty-three (43) separate procurement packages and cost estimates for each location and all work performed conformed to the UFC and Army design criteria.

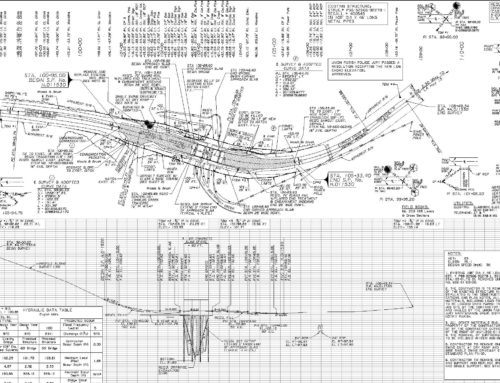

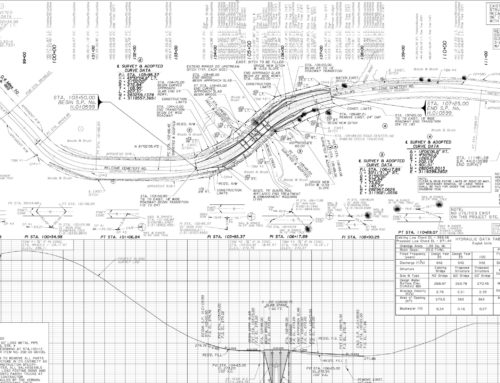

The project was located in the Cold Springs vicinity on Ben West Road, of the New Lands Training Area, north of Fort Polk. The project included replacement of an existing timber bridge, replacement of several other storm drainage pipes and low water crossing locations, along with clearing, grubbing, grading and stabilizing a 75’ wide RDW and addition of stone to 1.5 miles of widened existing installation road in order to improve safety in the training area of Fort Polk. Pavement sections for the bridge structure, low water crossings, and trail roads were engineered to satisfy the required life cycle design requirements for military heavy track vehicles (80 tons). A supplemental geotechnical investigation and paving recommendations provided by the geotechnical investigation were used to confirm the design and design concepts standards. Rigid concrete paving 12 inches thick was provided as the low water crossing. 10-inches of aggregate was designed to be placed as surface for the remainder of proposed trail improvements. The storm drain structures were sized based on a 25-year design storm hydraulic modeling. Preparation of final construction bid documents included two RCB bridge culverts and three reinforced concrete pipes were designed with headwalls and wingwalls, aprons, rip rap, water level gauges, object markers, and chevrons.

Construction Cost = $4.77M

Planning and Scheduling Management

The Ballard/KFNI project management team provided site survey and evaluation as part of the extensive up-front planning to minimize issues during detailed design. Ballard/KFNI conducted a multi-day design charrette to identify issues that needed to be addressed early on. Ballard/KFNI then conducted interviews with a variety of staff as a follow-up. The Cold Springs Culvert Repair Design-Build RFP was completed ahead of schedule and within budget, which allowed this task order to be executed as a FY16 year-end project.

Preparing Cost Estimates using MII and PACES

Ballard/KFNI utilized the services of a premier cost estimating firm for preparing estimates for USACE. They are highly skilled in the use of PACES, MCACES MII, and other estimating software. The estimate was accurate and reflected the construction environment at the time.

Preparing Drawings and Specifications for Issuing RFP

Ballard/KFNI provided a complete Ready to Advertise construction package that contained full scale drawings, SPECSINTACT specifications, design analyses, calculations and MII cost estimates for government use. The drawings were prepared and delivered in both AutoCAD (DWG) and Microstation v8i (DGN) CAD files.

Experience in providing quality designs consistent with the firm’s design quality management plan

Ballard/KFNI’s Quality Management Plan is a living document that is reexamined periodically for effectiveness in terms of providing high quality designs. Our engineers bring lessons learned to the forefront, so the Quality Plan reflects and incorporates our experience working on USACE projects. Such was the case with this project. Ballard/KFNI utilized our system of design basis review, coordination review, constructability review and Independent Technical Review to ensure high quality design.