Project Description

Ballard, Kenall, and Freese and Nichols (Ballard/KFNI-JV) provided A-E services to the Red River Army Deport (RRAD). FNI is the mentor firm in an 8(a) Mentor Protégé JV through USACE Fort Worth IDC No. W9126G-17-D-0011 with Kenall. The project scope included a total of twenty-nine (29) separate procurement packages and cost estimates that were to be divided into three separate task orders. The delivery award divides these procurement packages into three (3) tasks. The three tasks included:

Task 1 – Repair fire protection and suppression systems at buildings 323, 328, 345, 431, 441, 443 and 479 on RRAD.

Task 2 – Install security fences and gates at buildings 4, 15, 115, 116A-E, 184, 241 and 300 on RRAD.

Task 3 – Repair Fire Station, Boiler Manitenance, Fuel Tanker Testing, Enclose with Bridge Crane, Wash Rack buildings 4, 324, 324B, 397, 412B, 412D, 412E, 444, 444A, 448, 524 and 527 on the RRAD.

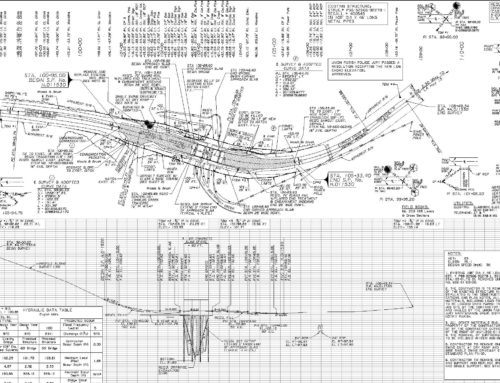

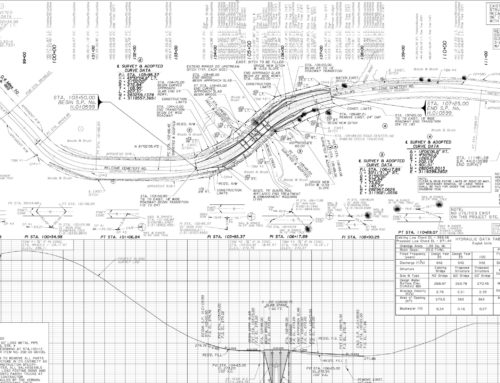

Ballard developed plans for security fences and gates as part of Task 2 and background drawings for Task 1. The Task 2 projects included the design of both palisade anti-scale heavy steel, and FE-6 high security chain link fencing totaling 7,200 linear feet overall. The fencing requirements also incorporated site lighting, and both pedestrian and vehicular gate access. Deliverables included 35%, 65%, 95% and 100% in both AutoCAD (DWG) and Microstation V8i (DGN) formats. These seven existing facilities are located within a campus that is open to the community at large. The installation was seeking to protect key command and control facilities to meet compliance with the UFC 4-010-01 for Antiterrorism Standards for Buildings. In meeting compliance, the project also incorporated compliance with UFC 4-022-03 for Infrastructure Design (Security Fences and Gates) as well as the use of Electronic Security Surveillance UFC. Ballard was the Designer of Record for 3 of 7 Facility scopes of work and provided technical support on remaining 4 projects with construction details and specifications. Ballard also provided survey and mapping (site topographical and utility surveying) for all 7 facilities. Included for each site, Ballard produced new and existing fencing and access control plans with demolition plans. Ballard incorporated site lighting and entry points utilizing the Common Access Control (CAC) cards through integration with the existing government CAC Access Control Systems. This includes multiple pedestrian and vehicular gates at each facility. The project also incorporated security camera monitoring at several of the facilities connected to central facility monitoring locations.

Planning and Scheduling Management

The Ballard/KFNI-JV project management team provided extensive up-front planning to minimize issues during detailed design. Ballard/KFNI-JV conducted a multi-day charrette to identify issues that needed to be addressed early on. Ballard/KFNI-JV then conducted interviews with a variety of staff as a follow-up. The fencing and gate designs were completed ahead of schedule and within budget, allowing the execution of the security fencing project. The Fire Protection and Building Repair tasks are on schedule and within budget. The project is over 90% complete with good interim performance for management and adherence to schedule, and cooperativeness and responsiveness.

Preparing Cost Estimates using MII and PACES

Ballard/KFNI-JV utilized the services of a premier cost estimating firm for preparing estimates for USACE. They are highly skilled in the use of PACES, MCACES MII, and other estimating software. The estimates provided at 35%, 65%, 95% and 100% review were accurate and reflected the construction environment at the time.

Preparing Drawings and Specifications

Ballard/KFNI-JV provided a complete Ready to Advertise construction package for fence project at Buildings 4, 15, and 300 that contained full scale drawings, SPECSINTACT specifications, design analyses, calculations and MII cost estimates for government use. The drawings were prepared and delivered in both AutoCAD (DWG) and Microstation v8i (DGN) CAD files.

Experience in providing quality designs consistent with the firm’s design quality management plan

Ballard/KFNI-JV’s Quality Management Plan is a living document that is reexamined periodically for effectiveness in terms of providing high quality designs. Our engineers bring lessons learned to the forefront, so the Quality Plan reflects and incorporates our experience working on USACE projects. Such was the case with this project. Ballard/KFNI-JV utilized our system of design basis review, coordination review, constructability review and Independent Technical Review to ensure high quality design.